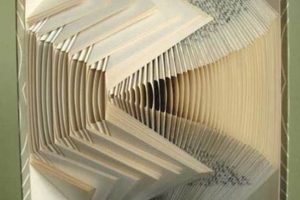

The creation of three-dimensional paper constructions is a craft involving paper engineering and artistic design. The process entails cutting, folding, and assembling paper components to create elements that rise from the page when it is opened. Achieving the desired effect requires careful planning and precise execution.

This craft provides a unique avenue for storytelling, allowing for dynamic visual representations that enhance engagement. Its historical significance lies in its evolution from simple movable illustrations in early books to complex artistic expressions. The resulting creations can be appreciated for both their mechanical ingenuity and aesthetic appeal.

The following sections will outline the materials required, fundamental techniques employed, and considerations necessary for crafting such paper constructions.

Essential Considerations for Three-Dimensional Paper Construction

The successful creation of three-dimensional paper structures hinges on meticulous planning and precise execution. Consider these recommendations to enhance the quality and durability of the final product.

Tip 1: Paper Selection is Paramount: The choice of paper weight and type significantly impacts the mechanism’s functionality. Heavier cardstock provides stability for structural components, while lighter paper is more suitable for folding and layering.

Tip 2: Employ Precise Cutting Techniques: Clean, accurate cuts are crucial for smooth movement and proper alignment. Utilize a sharp craft knife and a self-healing cutting mat to achieve professional results.

Tip 3: Master Fundamental Folds: Valley and mountain folds form the basis of most paper mechanisms. Consistent and crisp folds are essential for proper function and visual appeal. A bone folder can aid in achieving sharp creases.

Tip 4: Incorporate Adequate Glue Application: Use archival-quality adhesive sparingly to prevent warping or distortion of the paper. Precision glue applicators are recommended for controlled application.

Tip 5: Prioritize Mechanism Planning: Before commencing construction, carefully plan the mechanisms and their interaction. Create a mock-up or prototype to test functionality and identify potential issues.

Tip 6: Reinforce Stress Points: Identify areas of high stress within the mechanism and reinforce them with additional layers of paper or adhesive. This will increase the structure’s longevity and prevent tearing.

The adherence to these guidelines will greatly improve the quality and functionality of the final product. Diligent planning and skillful execution are crucial elements.

The following section will provide insight into troubleshooting common issues encountered during the construction process.

1. Planning

Effective development of three-dimensional paper constructions necessitates meticulous pre-production planning. This stage is critical for conceptualizing the design, determining the structural mechanics, and ensuring the cohesive integration of narrative and form. Adequate preparation significantly reduces potential complications during the construction phase.

- Conceptualization and Storyboarding

Conceptualization involves defining the narrative and visual themes to be represented in three dimensions. Storyboarding aids in visualizing the sequence of pop-up elements, their interactions, and their impact on the reader’s experience. For instance, in a children’s story, planning might involve identifying key scenes for pop-up illustration and mapping out how characters and objects will emerge from the page to enhance the storytelling.

- Mechanism Selection and Design

Mechanism selection is crucial for achieving the desired movement and visual effect. This includes choosing appropriate folds, levers, and linkages to animate the paper elements. Design of these mechanisms requires precision, considering factors such as paper thickness, hinge placement, and structural stability. An ill-chosen mechanism can lead to functional failure or aesthetic dissonance.

- Scale and Dimensional Considerations

Scale and dimensional considerations are paramount for ensuring visual harmony and structural integrity. The size of the pop-up elements must be proportionate to the page size and the overall design. Precise measurements and careful calculations are necessary to prevent overcrowding or instability. An improperly scaled element can disrupt the overall aesthetic and impair the function of the mechanism.

- Material Selection and Budgeting

The selection of appropriate materials, including paper stock, adhesives, and cutting tools, is vital for achieving a durable and visually appealing result. Budgeting considerations must factor in the cost of materials, equipment, and potential prototyping expenses. High-quality materials contribute to the longevity and professional appearance of the finished product, but must be balanced against budgetary constraints.

In summary, comprehensive pre-production work is foundational to the successful development of any three-dimensional paper construction. Attentive planning and execution of each step ensures functionality and enhances the final presentation. The investment in detailed preparation translates to a more refined and structurally sound outcome.

2. Mechanisms

The functionality of three-dimensional paper constructions is fundamentally dictated by the incorporated mechanisms. Without a properly designed and executed mechanism, a paper structure remains static, failing to achieve the intended dynamic effect. The selection and implementation of appropriate mechanisms are, therefore, critical components in the process. Examples of basic mechanisms include the V-fold, parallel fold, and rotational elements, each contributing a distinct type of movement and visual impact. The V-fold, for instance, creates a simple pop-up effect by elevating a shape as the page is opened. Failure to account for the paper’s properties, hinge placement, and load distribution can result in a malfunctioning or structurally unstable design.

The application of mechanisms extends beyond basic pop-up effects. Complex designs may integrate multiple mechanisms to achieve intricate movements or interactive elements. Consider, for instance, a book depicting a moving vehicle. Such a design might incorporate a combination of lever and linkage systems to simulate wheel rotation and chassis movement. Furthermore, the durability of the paper construction is directly influenced by the mechanism’s design. Overly complex or inadequately supported mechanisms are prone to failure with repeated use. In practical terms, a thorough understanding of mechanism principles is essential for producing lasting and engaging three-dimensional paper creations.

In summary, the interplay between mechanism design and structural integrity is central to the success of three-dimensional paper constructions. Understanding the capabilities and limitations of various mechanisms enables the creation of dynamic and functional designs. Challenges in this field often arise from the need to balance aesthetic complexity with structural robustness. Overcoming these challenges necessitates a systematic approach, combining theoretical knowledge with practical experimentation to achieve the desired functionality and durability.

3. Construction

The physical construction phase represents the tangible manifestation of design principles and pre-planned mechanisms in creating three-dimensional paper structures. This phase is critical to translating theoretical concepts into a functional, aesthetically pleasing, and durable physical form. The success of this phase directly impacts the overall effectiveness of the final product, and any deficiencies in execution can compromise the intended functionality and visual appeal.

Construction encompasses precise cutting, folding, and assembly of pre-designed components, following specific instructions derived from the planning stage. For example, incorrect cutting angles can prevent a pop-up element from deploying correctly, while imprecise folding can misalign components and obstruct the intended movement. Adhesion is a significant aspect; the type of adhesive and its application must be carefully controlled to ensure secure bonding without warping or distorting the paper. The structural integrity of the final piece is directly linked to the quality of the construction process. In situations involving complex mechanisms, such as multi-layered pop-ups or kinetic elements, the construction phase becomes exponentially more challenging, requiring meticulous attention to detail and careful sequencing of assembly steps.

Ultimately, mastery of construction techniques is indispensable for transforming design concepts into functional three-dimensional paper art. The interplay between accurate execution, appropriate materials, and adherence to design specifications determines the success of this process. Skillful construction not only ensures the structural integrity and functionality of the pop-up, but also significantly enhances its aesthetic appeal and longevity. The significance of this phase cannot be understated, as it represents the crucial link between conceptualization and realization in the realm of three-dimensional paper engineering.

4. Adhesion

Within the realm of three-dimensional paper engineering, adhesion serves as a critical parameter dictating the structural integrity and longevity. The effectiveness of how assembled paper components remain secured is directly attributable to the adhesive properties employed. In the context of constructing pop-up mechanisms, the selection of appropriate adhesives, coupled with meticulous application techniques, is paramount. An inadequate adhesive bond can lead to structural failure, preventing the intended kinetic movement. For example, using a weak or inappropriate adhesive on a complex parallel fold mechanism risks the separation of layers under stress, rendering the entire system non-functional. Conversely, excessive application of certain adhesives can cause warping or distortion of the paper, also negatively impacting performance.

Practical applications necessitate careful consideration of adhesive properties such as open time, bond strength, and flexibility. Open time refers to the period during which the adhesive remains workable, enabling accurate placement of components. Bond strength dictates the adhesive’s resistance to separation under applied force. Flexibility ensures that the adhesive bond does not become brittle over time, which is crucial for mechanisms subjected to repeated movement. Examples of suitable adhesives include polyvinyl acetate (PVA) glues, known for their archival quality and flexibility, and certain types of pressure-sensitive adhesives (PSAs) for temporary or repositionable bonds. The choice of adhesive should align with the specific materials and mechanical demands of the particular pop-up structure.

In summary, the appropriate selection and application of adhesives are essential components of three-dimensional paper construction. Adhesion’s primary function is maintaining the structural integrity and mechanical functionality of pop-up elements. Challenges may arise from selecting adhesives with incompatible properties or employing improper application techniques. Understanding these nuances allows designers to mitigate potential failures and produce durable, visually engaging, and functionally sound paper creations.

5. Refinement

In the creation process of three-dimensional paper constructions, refinement constitutes the final stage where meticulous adjustments and optimizations are applied to the structure. This stage is critical for enhancing the aesthetic appeal, functional performance, and overall durability. Without systematic refinement, imperfections in construction can compromise the structural integrity and diminish the intended visual impact.

- Structural Reinforcement

Structural reinforcement involves identifying and addressing any weak points or areas of high stress within the paper construction. This may include adding reinforcing elements such as additional layers of paper, strategic application of adhesive, or modifying fold patterns to distribute stress more evenly. For instance, reinforcing hinge points in a parallel fold mechanism prevents tearing under repeated use, thereby extending the lifespan of the pop-up element.

- Aesthetic Adjustments

Aesthetic adjustments encompass fine-tuning the visual elements of the design to achieve the desired aesthetic impact. This may include trimming excess paper, correcting misalignments, or adding decorative details to enhance the overall presentation. Consider the edges of a pop-up element; clean, precise edges contribute to a professional appearance, whereas jagged or uneven edges detract from the overall aesthetic.

- Functional Optimization

Functional optimization focuses on ensuring that all mechanisms operate smoothly and reliably. This may involve adjusting fold angles, modifying hinge positions, or lubricating moving parts to reduce friction. For example, a rotational element may require adjustment to ensure it rotates freely without binding, thus maximizing its visual effect and minimizing stress on the surrounding structure.

- Quality Control and Testing

Quality control and testing involve a systematic evaluation of the completed paper construction to identify any remaining defects or areas for improvement. This may include subjecting the pop-up to repeated cycles of opening and closing to assess its durability and functionality. Any identified issues are then addressed through further refinement. Comprehensive testing ensures that the final product meets the desired standards of quality and performance.

In essence, refinement is a critical iterative process that elevates three-dimensional paper constructions from conceptual designs to polished, functional art pieces. The attention to detail during this phase directly translates into a superior final product, characterized by enhanced aesthetic appeal, robust structural integrity, and optimized functionality. Neglecting refinement can result in a subpar outcome that fails to realize the full potential of the initial design concept.

Frequently Asked Questions Regarding Three-Dimensional Paper Construction

This section addresses common inquiries pertaining to the principles and practices involved in the creation of interactive paper-based structures.

Question 1: What is the appropriate weight of paper for constructing pop-up mechanisms?

The selection of paper weight is contingent upon the structural demands of the mechanism. Heavier cardstock, typically ranging from 65lb to 100lb, provides greater stability for load-bearing components. Lighter paper, generally 20lb to 60lb, is more suitable for intricate folds and layering where flexibility is prioritized.

Question 2: Which type of adhesive is recommended for bonding paper components?

Archival-quality, pH-neutral adhesives are advisable for ensuring the longevity of the paper construction. Polyvinyl acetate (PVA) glues and certain pressure-sensitive adhesives (PSAs) are commonly employed, offering a balance of bond strength and flexibility. Cyanoacrylate adhesives (super glues) are generally discouraged due to their potential to embrittle paper fibers.

Question 3: What tools are essential for constructing precise paper mechanisms?

Essential tools include a sharp craft knife or scalpel, a self-healing cutting mat, a metal ruler, a bone folder for creating crisp folds, and precision glue applicators. Specialized tools such as compass cutters and scoring boards can facilitate the creation of complex shapes and consistent folds.

Question 4: How does one prevent warping when applying adhesive to paper?

To minimize warping, adhesive should be applied sparingly and evenly. Utilizing a glue applicator with a fine tip allows for controlled application. After bonding, the paper construction can be placed under a weighted flat surface to prevent distortion during the drying process.

Question 5: What are the key considerations for designing a functional V-fold mechanism?

Critical design factors for V-fold mechanisms include accurate angle measurements, precise cutting and folding, and proper alignment of the hinged components. The paper stock must be strong enough to withstand repeated folding and unfolding without tearing. Reinforcement of the hinge points with additional paper or adhesive may be necessary.

Question 6: How can one troubleshoot a pop-up mechanism that fails to deploy correctly?

Troubleshooting involves a systematic examination of the mechanism for obstructions, misalignments, or structural weaknesses. Verify that all folds are properly creased and that all components are correctly positioned. Reinforce any areas of excessive stress or potential failure. If the mechanism is too tight, easing the folds or slightly increasing the dimensions of the moving parts may be required.

In summary, the successful creation of intricate paper structures hinges on careful material selection, precise execution, and a thorough understanding of fundamental mechanical principles. Addressing these key considerations can significantly enhance the quality and functionality of the final product.

The following section will explore the artistic and narrative aspects of three-dimensional paper constructions.

Conclusion

The preceding exploration into the mechanics and artistry of three-dimensional paper construction, encompassing planning, mechanism design, construction, adhesion techniques, and refinement processes, highlights the multifaceted nature of the discipline. The ability to execute complex paper mechanisms is contingent upon a thorough understanding of these interwoven elements. Mastery requires dedicated study and practical application.

Therefore, the effective creation of interactive paper-based structures necessitates not only technical proficiency but also a capacity for creative problem-solving and aesthetic judgment. Continued advancement in this field relies on the dissemination of knowledge and the exploration of innovative design approaches. The future of three-dimensional paper engineering lies in pushing the boundaries of both structural complexity and narrative expression.

![Why They Still Make Phone Books [The Truth] BoneyBooks | Discover Rare Books, Timeless Classics & Modern Reads Online Why They Still Make Phone Books [The Truth] | BoneyBooks | Discover Rare Books, Timeless Classics & Modern Reads Online](https://boneybooks.com/wp-content/uploads/2025/06/th-226-300x200.jpg)