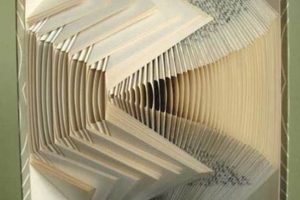

The construction of three-dimensional, movable paper structures integrated within a book format involves meticulous design and precise execution. These creations, often called movable books, utilize techniques like layering, folding, and linking paper components to achieve dynamic effects when a page is turned. A simple example includes a greeting card where a shape “pops up” upon opening; however, these principles can be expanded to create complex scenes and mechanisms within the confines of a bound book.

Movable books hold significance in education, entertainment, and artistic expression. Their interactive nature can enhance engagement and comprehension, particularly for visual learners. Historically, these formats provided early forms of amusement and instruction, evolving from simple astronomical diagrams to intricate storytelling devices. The tactile experience and visual impact contribute to memorable and impactful communication.

Understanding the creation of these engineered paper mechanisms necessitates exploring fundamental structural techniques, material selection, and binding considerations. A systematic approach will facilitate the realization of compelling and functional movable book designs.

Essential Techniques for Movable Book Construction

Achieving successful movable book projects demands meticulous planning and execution. The following guidelines offer key insights into various stages of the development process.

Tip 1: Prioritize Structural Integrity: Secure and reliable paper engineering is essential. Thorough testing of moving parts ensures longevity and prevents premature wear or breakage.

Tip 2: Select Appropriate Paper Weight and Type: The choice of paper influences durability and performance. Heavier stock enhances sturdiness, while smoother finishes are suitable for detailed printing and intricate folds.

Tip 3: Employ Precise Cutting and Scoring Techniques: Accurate cutting and scoring are critical for flawless mechanisms. Consider using tools like cutting machines or scoring boards to guarantee precision.

Tip 4: Utilize Strategic Adhesion Methods: The adhesives selected must provide a strong bond without distorting the paper. Archival-quality glues or tapes are recommended to prevent discoloration and degradation over time.

Tip 5: Design with Page Thickness in Mind: Account for the increased bulk resulting from the three-dimensional elements. Modify the spine and binding method as needed to accommodate the cumulative thickness of the pages.

Tip 6: Prototype and Iterate Extensively: Create multiple prototypes to refine the design and identify potential weaknesses. Iterative testing allows for early detection of problems and promotes continuous improvement.

Tip 7: Consider the User Experience: Design interactive elements to be intuitive and engaging. Simplicity often contributes to a more positive user experience.

Adhering to these principles will significantly enhance the structural soundness and user appeal of movable book projects. Applying these technical insights ensures effective execution and lasting quality.

The next step involves delving into the intricacies of specific pop-up mechanisms and binding techniques, expanding upon the foundation laid by these fundamental considerations.

1. Paper Engineering Principles

Paper engineering principles constitute the foundational knowledge required for the successful creation of movable books. These principles govern how paper is manipulated to achieve dynamic, three-dimensional effects, making them indispensable for anyone undertaking such a project. A thorough understanding of these principles ensures the stability, functionality, and aesthetic appeal of the final product.

- Folding Techniques

Folding is the cornerstone of paper engineering, enabling the creation of pop-up elements and mechanical linkages. Various folding techniques, such as valley folds, mountain folds, and reverse folds, are employed to achieve different effects. In movable books, strategic folding allows flat sheets of paper to transform into complex structures when the page is opened, creating visual depth and movement. Misunderstanding these techniques leads to structural instability and non-functional mechanisms.

- Cutting and Scoring

Precise cutting and scoring are essential for accurate movement and clean aesthetics. Cutting separates portions of the paper to allow for movement, while scoring creates defined lines along which the paper can fold smoothly. In movable books, these techniques are used to create hinges, flaps, and other moving components. Inaccurate cutting or scoring results in ragged edges and compromised functionality.

- Leverage and Mechanical Advantage

The application of leverage and mechanical advantage allows for complex movements with minimal user input. Levers can amplify the force applied when a page is turned, creating more dramatic and intricate pop-up effects. In movable books, understanding these concepts enables the creation of mechanisms that require minimal effort to operate. Failing to apply leverage effectively can result in mechanisms that are difficult or impossible to activate.

- Structural Support and Reinforcement

Ensuring the structural integrity of movable elements requires careful consideration of support and reinforcement. Techniques such as layering, gluing, and the use of internal supports can enhance the stability and durability of pop-up structures. In movable books, these methods prevent the mechanisms from collapsing or tearing under repeated use. Neglecting structural support leads to fragile designs prone to damage.

The integration of these facets collectively defines the realm of paper engineering principles and directly influences the feasibility and success of any movable book project. Mastery of these techniques enables designers to create intricate and engaging designs, underscoring their critical importance. The effective application of these principles allows for the realization of sophisticated mechanisms and enduring quality.

2. Precise Cutting Techniques

Precise cutting techniques are indispensable in the construction of movable books. The accuracy and quality of cuts directly impact the functionality, aesthetics, and structural integrity of the final product. Flawless execution in cutting is not merely an aesthetic consideration but a prerequisite for achieving complex paper mechanisms.

- Laser Cutting

Laser cutting utilizes a focused laser beam to precisely cut materials, offering unparalleled accuracy and the ability to create intricate designs. In the context of movable books, laser cutting enables the creation of complex geometric patterns and fine details that would be difficult or impossible to achieve manually. This technique is particularly useful for mass production or when replicating highly intricate designs. However, laser cutting may produce slightly charred edges, which must be considered during the design phase. The capital investment for laser cutting equipment can be significant.

- Die Cutting

Die cutting involves using a specialized tool (a die) to stamp out shapes from paper. This method is highly efficient for producing identical shapes in large quantities. In the creation of movable books, die cutting is often employed for repetitive elements, such as tabs, slots, and decorative shapes. The initial cost of creating a die can be substantial, but the per-unit cost decreases significantly with increased production volume. Die cutting results in clean, uniform cuts and is suitable for a wide range of paper thicknesses.

- Craft Knife Cutting

Craft knife cutting, executed with a sharp blade and a steady hand, allows for precise control over intricate cuts. This method is particularly suitable for small-scale projects or when creating prototypes. In movable books, craft knife cutting enables the creation of custom shapes and details that may not be feasible with other methods. However, this technique requires significant skill and patience and is less efficient for mass production. It offers flexibility in design modification and is cost-effective for one-off creations.

- Digital Cutting Machines

Digital cutting machines, such as those used in scrapbooking and crafting, offer a balance between manual and automated cutting techniques. These machines utilize a small blade to cut shapes based on digital designs. They are suitable for creating moderately complex designs and offer greater precision than manual cutting. In the context of movable books, digital cutting machines can be used to create intricate patterns and shapes with relative ease. They are more affordable than laser or die cutting and provide a versatile option for hobbyists and small businesses. The designs must be digitally prepared, adding an initial setup step.

The choice of precise cutting technique depends on the scale of the project, the complexity of the design, and the available resources. Whether utilizing advanced technology like laser cutting or employing traditional methods with a craft knife, accurate cuts are essential for the successful construction and functionality of any movable book. Mastery of these techniques directly translates to a higher quality, more durable, and visually appealing final product, furthering the art of paper engineering.

3. Adhesive Application Methods

Adhesive application methods are critical in the assembly and structural integrity of movable books. The appropriate selection and precise application of adhesives directly impact the durability, functionality, and aesthetic quality of these engineered paper structures.

- Glue Sticks

Glue sticks offer a clean and convenient method for bonding paper components, particularly for lightweight materials and broad surface areas. They provide a temporary or semi-permanent bond, allowing for repositioning during assembly. However, the bond strength of glue sticks may be insufficient for high-stress areas or heavier paper stock, potentially leading to premature failure in moving parts. Their ease of use makes them suitable for initial assembly stages but not final structural reinforcement.

- Liquid Glues

Liquid glues, encompassing varieties like PVA (polyvinyl acetate) and archival-quality options, provide a strong and permanent bond suitable for securing complex paper mechanisms. PVA glue is known for its flexibility and water resistance, while archival glues are formulated to prevent discoloration and degradation over time, preserving the integrity of the movable book. The application of liquid glues requires precision to avoid excess adhesive, which can cause warping or staining. Controlled application methods, such as fine-tipped applicators, are recommended.

- Double-Sided Tapes

Double-sided tapes offer a clean and immediate bonding solution, eliminating the drying time associated with liquid glues. They are particularly useful for adhering small components or creating layered effects. The strength and permanence of double-sided tapes vary, with some products offering archival-quality and high-tack adhesion. Precision in placement is crucial, as repositioning after application may damage the paper. Thicker tapes can also add unwanted bulk, impacting the smooth operation of moving parts.

- Glue Dots

Glue dots are small, pre-formed adhesive circles that provide a quick and precise method for bonding intricate details. They are suitable for attaching small embellishments or reinforcing specific areas of a paper mechanism. The adhesive strength of glue dots varies, with options available for both temporary and permanent bonds. They eliminate the mess and drying time associated with liquid glues, offering a clean and efficient solution. However, the small size of glue dots limits their use to specific applications, and they may not be suitable for bonding larger surfaces or high-stress areas.

These adhesive application methods, when strategically employed, contribute to the robust construction and long-term preservation of movable books. Selecting the appropriate adhesive and applying it with precision is paramount in ensuring the functionality and durability of these intricate paper creations. Each method offers unique advantages and limitations, necessitating careful consideration during the design and assembly process.

4. Structural Reinforcement Strategies

Structural reinforcement strategies are integral to the creation of durable and functional movable books. These strategies address the inherent fragility of paper and the stress placed upon it by moving parts, thereby ensuring the longevity and operational effectiveness of the book’s mechanisms.

- Lamination and Coating

The application of lamination or protective coatings enhances paper strength and resistance to tearing and moisture. Lamination involves bonding a thin plastic film to the paper surface, providing a barrier against physical damage and environmental factors. Coatings, such as UV or varnish, offer a similar level of protection with varying degrees of gloss and durability. In movable books, lamination is particularly beneficial for frequently handled components, such as tabs and flaps, preventing wear and tear. For instance, children’s movable books often utilize laminated surfaces to withstand rough handling. The implications include increased cost and potential inflexibility in design.

- Paper Grain Orientation

The orientation of paper grain significantly influences its folding and tearing characteristics. Paper folds more easily and cleanly along the grain, while folding against the grain can lead to cracking and weakened creases. When designing movable books, aligning the paper grain with the intended fold lines minimizes stress on the paper fibers, enhancing the structural integrity of the mechanisms. For example, a valley fold should ideally run parallel to the paper grain to ensure a crisp, clean crease. Failure to consider grain orientation can result in brittle hinges and reduced operational lifespan.

- Hinge Reinforcement

Hinges, the points where moving parts connect and pivot, are particularly vulnerable to stress and fatigue. Reinforcing hinges with additional layers of paper, fabric, or adhesive tape strengthens these critical areas, preventing tearing and ensuring smooth operation. In movable books, hinge reinforcement is essential for components that undergo frequent movement, such as pop-up elements and rotating parts. An example is the use of thin strips of linen tape to reinforce the spine of a pop-up card, allowing it to be opened and closed repeatedly without damage. Neglecting hinge reinforcement leads to premature failure of the moving parts.

- Internal Supports and Gussets

Internal supports and gussets provide additional stability to complex pop-up structures. These elements, often concealed within the design, distribute stress and prevent collapse. Internal supports can take the form of hidden tabs, struts, or connecting panels, while gussets are triangular or rectangular reinforcements placed at corners and joints. In movable books, these elements are crucial for supporting large or intricate pop-up elements, such as buildings or complex machinery. For instance, a complex castle pop-up might employ hidden cardboard struts to support the weight of the towers. Lack of internal support results in unstable and easily damaged pop-up elements.

The effective implementation of these structural reinforcement strategies is paramount to the creation of durable and engaging movable books. By addressing the inherent limitations of paper and mitigating stress points, these techniques ensure that the mechanisms function reliably and withstand the rigors of repeated use. Strategic reinforcement contributes to the overall quality and longevity of the finished product, aligning directly with the objectives of skillful paper engineering.

5. Binding Compatibility Considerations

The selection of a suitable binding method is paramount in movable book construction. The addition of three-dimensional elements and paper mechanisms significantly alters the overall thickness and structural integrity of the book block. Thus, traditional binding techniques may prove inadequate or require modification to accommodate the unique challenges presented by movable book designs.

- Spine Thickness Accommodation

The integration of pop-up elements and folded mechanisms invariably increases the overall thickness of individual pages and, consequently, the spine of the book. Binding methods must be selected or adapted to accommodate this increased bulk without compromising the book’s structural integrity or aesthetic appeal. Standard binding techniques like saddle stitching are generally unsuitable due to their limitations in handling thick book blocks. Methods such as case binding or spiral binding may require spacers or adjustments to the spine width to ensure proper closure and durability. An inadequately sized spine can lead to distorted page alignment, difficulty in opening and closing the book, and premature wear.

- Page Movement and Stress

Movable books inherently involve repetitive manipulation of individual pages and integrated mechanisms. The chosen binding must allow for smooth and unrestricted page movement while withstanding the stress imposed by the operation of pop-up elements. Binding methods that restrict page movement or create excessive tension can hinder the functionality of the mechanisms and accelerate wear and tear. For example, perfect binding, while aesthetically pleasing, may not provide sufficient flexibility for pages containing complex pop-up structures, potentially leading to detachment or damage over time. Consideration must be given to the binding’s ability to distribute stress evenly and prevent localized points of failure.

- Weight Distribution and Balance

The asymmetrical distribution of weight resulting from pop-up elements and paper mechanisms can pose challenges to the overall balance and stability of the book. Binding methods must be chosen to counteract these imbalances and ensure that the book lies flat when opened, preventing undue stress on the spine and individual pages. Techniques such as incorporating heavier endpapers or adjusting the placement of pop-up elements can contribute to improved weight distribution. Failures to address weight imbalances can lead to warping, distortion, and reduced longevity of the finished product. A book that consistently falls open to a specific page due to uneven weight distribution is a clear indication of binding incompatibility.

- Material Compatibility

The materials used in the binding process, including adhesives, threads, and cover boards, must be compatible with the paper types and coatings used in the creation of the movable book. Incompatible materials can lead to chemical reactions, discoloration, or weakened bonds, compromising the book’s structural integrity and aesthetic appearance. For example, acidic adhesives can cause yellowing or embrittlement of the paper over time, while certain coatings may interfere with the adhesion of binding materials. Thorough testing of material compatibility is essential to ensure the long-term preservation and functionality of the finished product. This includes considering the archival qualities of all binding components.

These binding compatibility considerations are not merely technical details, but fundamental aspects dictating the success of movable book projects. Addressing these elements effectively transforms the undertaking into a robust and captivating interactive experience, underscoring their vital contribution to the artistry and function of this unique medium. Neglecting these considerations will almost certainly result in a structurally unsound and disappointing final product.

Frequently Asked Questions

This section addresses common inquiries regarding the creation of movable books, providing concise and informative responses based on established paper engineering principles.

Question 1: What are the essential tools required for creating pop-up books?

The fundamental toolkit typically includes a craft knife, cutting mat, metal ruler, bone folder, various adhesives (liquid glue, glue stick, double-sided tape), and a printer for design output. Specialized tools such as a die-cutting machine or laser cutter may be employed for more intricate designs, but are not essential for basic construction.

Question 2: What types of paper are most suitable for movable book construction?

Medium-weight cardstock (65-100 lb cover) is generally recommended due to its balance of flexibility and rigidity. The choice of paper finish depends on the desired aesthetic, with matte finishes offering better adhesion for glues, while glossy finishes provide a more vibrant visual appearance. Archival-quality paper should be considered for projects intended for long-term preservation.

Question 3: How can structural integrity be ensured in complex pop-up mechanisms?

Employing techniques such as hinge reinforcement, internal supports, and gussets significantly enhances the stability of intricate pop-up elements. Careful consideration of paper grain orientation and strategic adhesive placement also contributes to overall structural integrity. Prototyping and iterative testing are crucial for identifying and addressing potential weaknesses in the design.

Question 4: What are the key considerations for designing a functional and engaging pop-up book?

User experience should be prioritized, ensuring that pop-up mechanisms are intuitive and easy to operate. Simplicity in design often contributes to greater functionality and durability. Consider the target audience and tailor the complexity and themes of the pop-up elements accordingly. Thorough testing and refinement are essential for achieving a balance between visual appeal and operational reliability.

Question 5: How can the increased thickness caused by pop-up elements be accommodated in the binding process?

Adjustments to the spine width are necessary to accommodate the added bulk resulting from the inclusion of pop-up elements. Binding methods such as case binding or spiral binding may require modifications to ensure proper closure and page alignment. The selection of a flexible binding adhesive and the incorporation of heavier endpapers can also contribute to a more balanced and structurally sound final product.

Question 6: What steps should be taken to prevent damage to pop-up mechanisms during storage and handling?

Careful storage is essential for preserving the integrity of pop-up books. Store the book in a cool, dry environment away from direct sunlight and extreme temperature fluctuations. Consider using a custom-fitted slipcase or box to protect the book from physical damage. Gentle handling and careful operation of the pop-up elements will minimize the risk of tearing or bending.

These FAQs provide a foundation for understanding and addressing common challenges encountered during the creation of pop-up books. Further exploration and experimentation will enhance proficiency and enable the creation of increasingly sophisticated and engaging designs.

The following section will explore advanced techniques and alternative approaches for creating unique and innovative movable book designs.

Conclusion

This exploration of “how to make a pop book” has addressed core principles and practical techniques crucial for constructing these interactive paper structures. From understanding paper engineering fundamentals to selecting appropriate adhesives and binding methods, the presented information provides a comprehensive foundation. Mastery of precise cutting, strategic reinforcement, and design considerations are paramount for creating functional and aesthetically compelling movable books.

Continued dedication to refining these skills will foster innovation in paper engineering and empower creators to push the boundaries of this unique art form. The construction of movable books demands meticulous attention to detail and a deep understanding of materials, principles that translate to a diverse range of creative endeavors, positioning the gained knowledge as invaluable for both artistic expression and technical expertise.

![Why They Still Make Phone Books [The Truth] BoneyBooks | Discover Rare Books, Timeless Classics & Modern Reads Online Why They Still Make Phone Books [The Truth] | BoneyBooks | Discover Rare Books, Timeless Classics & Modern Reads Online](https://boneybooks.com/wp-content/uploads/2025/06/th-226-300x200.jpg)